In the fiercer Singapore environment, preventive maintenance is no longer a luxury. It is a necessity. Buildings and infrastructure like roads, railways, and electrical grids must resist the attack of temperature and humidity almost daily. Meet thermal imagers, not only maintenance superheroes but also those equipped with the capabilities of seeing things the unaided eye cannot do.

While these advanced gadgets collect infrared radiation, they provide us with the opportunity to see the temperature distribution and identify potential trouble spots before they appear in terms of physical symptoms. Adios to manual supervision of power plants with thermal imagers, which provides a proactive solution for nipping problems in the bud.

But that’s not all. If you have humidity loggers, pair them with thermal imagers, and they will become an unbeatable duo. Humidity devices monitor moisture levels and transmit the information to more thermal imaging findings. They work in synergy to guarantee that no rooms are left out of the picture in the struggle to achieve a properly maintained, energy-efficient, built world.

Through this blog article, we will showcase Singapore’s top 5 industrial applications of thermal imagers and how this breakthrough technology is making maintenance and troubleshooting efforts more convenient.

1. Early Detection of Building Envelope Issues

Just imagine all this from a bird’ s-eye view: air leakage, moisture intrusion, and insulation inadequacy before they can ruin your building’s structural integrity. That is the power of thermal imaging technology. They can detect temperature variations, directly pointing to where the heat is escaping or moisture is seeping. Thus, you’ll be able to do something about it before the mould party starts in your walls.

The date of detection is of the utmost importance when discussing issues about building envelopes. Today, a small leak could develop into a major leak nightmare tomorrow, not to mention the possible health problems that may arise due to mould that is not checked. Let me tell you, that corridor of mouldy breadcrumbs is not where you want to go!

Taking thermal imaging with humidity loggers allows you to have a dynamic pair that will monitor moisture levels and give you early reports before you see any signs of this problem on your thermal imager.

Actionable Tip: Integrate routine thermal imagers with humidity measurements into your maintenance audit. Your building’s safety will enjoy the compliment, and your spirit will, too, with the comfort of knowing that the moisture problems are under control.

People Also Ask:

1. Can thermal imaging cameras spot water leaks?

Absolutely! Thermal imagers provide a difference in temperature due to moisture penetration, making them very useful tools for discovering hidden leaks.

2. What should be the red flags that a building envelope issue is present?

Among these indicators are leaks, condensation formation, mould development, and unexplainable increases in energy bills. However, thermal imagers catch the issues in time before they become visible without eyesight help.

2. Proactive Maintenance of Electrical Systems.

Electrical systems are the lifeline of any modern building, but they can also be tricky power centres if they must be appropriately maintained. Overheated components, looseness of connections, and conceivable electrical hazards, including fire, are some wild creatures found in neglected electrical panels and equipment.

In goes the thermal imagers, the guardian angels of electrical safety technology. The discovery of thermal deviations helps classify issues into electrical ones before they become emergencies. Okay, now visualise having the ability to catch a faulty breaker or overheating transformer before it decides to break. You will be able to prevent the “sparky tantrum.”

Actionable Tip: Develop a regular electric thermal inspection plan for your electric panels and critical equipment, particularly for high-rise buildings and facilities with large electrical systems.

People Also Ask:

1. What intervals shall be recommended for conducting regular visual inspections with thermal imagers?

The recommendation is to conduct thermographic inspections of electrical panels once annually or twice yearly, depending on the age and workload of the devices.

2. And what are the threats of overheating electrical components?

The heat generated by electrical elements may trigger component damage, augmenting fire threats or downtimes due to interruptions. It will be a great disaster if we don’t take care of this, and it will happen only when proactive thermal imaging inspections are ignored.

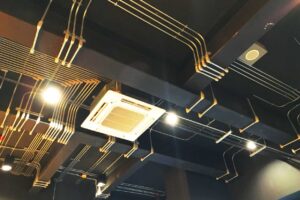

3. Streamlining HVAC System Efficiency.

It is no secret that a reliable air conditioning system is indispensable in Singapore’s hot and humid climate. It is both a luxury and a basic requirement for a comfortable indoor temperature. Nevertheless, dirty air filters, duct leaks, and inefficiencies can turn your cooling system into an expensive money pit that consumes energy.

Thermal imagers, the heroes of unseen work in HAVC optimisation, have entered the stage. With their capability of revealing temperature patterns, these gadgets can detect places that are losing or gaining heat, thereby pinpointing possible duct leaks and probable inefficiencies that might be causing substantial energy bills.

But why stop there? A thermal imager and a humidity logger can create a dynamic duo that monitors indoor humidity levels and saves the HVAC system from operational breakdowns. It’s like having a climate control supervisor who doesn’t wear a costly robe with a crystal ball.

Actionable Tip: Schedule HVAC thermal inspections as a routine part of your preventive maintenance process. Furthermore, your system will identify and fix upcoming issues before they interfere with your convenience or energy bills, and you will not only benefit from this but also have an opportunity to boast about your neighbours’ surprise about your extraordinary maintenance tactics.

People Also Ask:

1. What do thermal imagers offer in thermal imaging to improve HVAC efficiency?

Thermal imagers can identify heat loss or gain through ductwork, lack of insulation, or air flow blockages, helping you locate the areas that are reducing the efficiency of your HVAC.

2. What does an inefficient HVAC sign look like?

A significant manifestation of this is inconsistent heating or cooling, high energy bills, and loud noises/vibrations. A thermography scan can give away the exact reason for an unbalanced load.

4. Safeguarding Public Health and Safety.

In a highly populated country like Singapore, public health and safety should be of the highest concern. From thermal fever scans to fumigation and pest control inspection, this technology is becoming our greatest ally for protecting our community’s health.

Visualise the case where you can pinpoint the elevation in body temperatures from a secure location, enabling accurate fever screening at crowded spots, such as airports or transport hubs. Thermal imagers have contributed to the discovery of potential COVID-19 cases, facilitating the containment of the spread of the virus by shielding the high-risk population.

However, the applications aren’t limited to these areas. Thermal scanners also identify the risks of overheating, for instance, in the case of overloaded electrical equipment or construction defects in public and private spaces. We can take immediate action to prevent those hazardous incidents before they ruin the public health and safety

5. Enhancing Productivity and Quality Control in Manufacturing

In a manufacturing world where time is running at an alarming speed, every downtime should be avoided. Hence, downtime should be considered as an eight-letter word, which gives fear to all production managers. But this is where thermal imagers come in place, and they operate like a superhero that flies in this situation to save the day.

By monitoring the health status of machines and equipment with thermal imaging technology, you can forecast any failure before the time it happens, which not only helps in scheduling maintenance activities but also prevents expensive production interruptions. It’s the same as having a crystal ball that can read the future. However, you won’t be involved in knowing the future, but some crucial things about your industrial assets do.

Actionable Tip: Time is priceless, and you can’t afford to let it go to waste. Therefore, start using thermal imaging for process monitoring and any equipment where you suspect some anomaly. In addition to having the requirement of bringing light to possible issues before they cause devastating temporary shutdowns, the competition edge will also be enhanced by making it possible to have consistent product quality.

People Also Ask:

1. How can thermography enhance product quality?

Infrared cameras can be valuable tools in identifying temperature anomalies or hot spots in the manufacturing process, including the issues that may lead to product defects or quality control problems.

Conclusion.

Employing thermal imagers is now a must-have for maintenance and troubleshooting technicians who work in the dynamic Singaporean environment. Be it from finding building envelope issues to ensuring public health and safety, these tools make it possible to have a proactive approach by finding and fixing potential issues before the problems even develop.

Nevertheless, thermal cameras are not only used for troubleshooting and inspection; they also play a key role in improving efficiency in the manufacturing process and maintaining product quality. Thermal imaging, which can be used to monitor machinery, find potential failures, and identify process inefficiencies, is no less than a game-changer for industries that have zero tolerance for downtime and costly ones.

Therefore, if you are a member of facilities management, a public health official, or a production manager, now is the time to leverage the power of thermal imaging. By blending this cutting-edge technology with the usual monitoring techniques and humidity logger readings, you will be able to produce a sophisticated maintenance strategy that will ensure that your assets stay in top condition and that your operations work smoothly.

Think of a scenario where you can spy the trouble unfolding before it is too late, where you are always a step ahead against the problems. This is the kind of future that thermal imagers are cruising in, and it is a future that is already knocking on Singaporeans’ front doors. Hence, what are you still waiting for? Join the thermal imaging movement and know the peace of mind that comes with thorough maintenance prevention.